ACDi’s in-house test team provides a comprehensive array of test solutions to meet our customers’ functionality and reliability requirements. We have demonstrated capabilities to deploy box level systems test and automated configurations. Capabilities include functional testing, static and dynamic burn-in, software download, EEPROM/Flash configurations and MAC ID programming.

These test solutions (defined below) are to detect and diagnose manufacturing, component and design defects early on in process promoting efficiency and cost management. The early involvement of the ACDi test team in the manufacturing process ensures that only quality product moves to shipment and reaches the end-user.

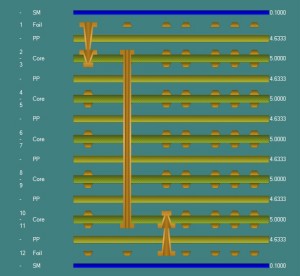

Flying Probe/ICT

In-circuit test

• Flying Probe testers for NPI and low volume production to keep software and fixture development costs to a minimum

• Teradyne and HP in-circuit testers are utilized for high volume production testing

• Capability to program and flash devices at in-circuit test as well as boundary scan testing

• Design and development of test fixtures and software programs to enhance testing capabilities

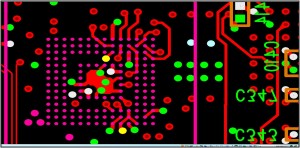

Automated Optic Inspection (AOI)

• Verify component presence, placement, orientation, and soldering prior to Flying Probe testing

NPI test solutions

• Initial review of designs for testability performed by test engineering staff

• Maximization of test coverage- our distributed test plan includes AXI, Flying Probe test, boundary scan and bench testing

Functional/JTAG

• Design customized functional test solutions utilizing custom software and National Instrument’s VISA libraries, rack & stack and other test hardware solutions.

• Participation in early design phases to review testability, built in self- test, boundary scan and cluster testing and finalization of test plans

• JTAG boundary scan contains features to build-in debugging to prevent faults in prototypes, moving them to production faster

• Teaming with customers to convert customer owned engineering test systems to manufacturing test solutions by incorporating bed of nails, test operator front panels, fused protection, and cabling.

• Deployment of reliability test solutions including ESS, HASS and ORT testing

• Designed for early failure mode detection, design robustness and parameter drift detections

• Test cable and harness interconnects and backplane devices- check for continuity, opens, shorts, insulation resistance, passive components and hi-pot testing

Integration and Custom Services

• System configuration

• Full hardware & sheet metal procurement services

• Simple box build to rack assemblies

• Customer direct ships/ finished goods

• Mechanical assembly

• Electrical sub-assemblies

• Conformal Coating

• Rework of fine pitch components and complex BGAs while ensuring proper conformance levels

• Warranty Services- provided for turnkey and kit jobs

• Repair depot services